Defence in depth

Design and operation aspects

- adoption of conservative design;

- quality control;

- stringent operation procedures;

- surveillance to detect degradation or failure; and

- establishment of a safety culture.

Reactor protection system

- Multiple reactor protection systems operating on different principles are provided so as to promptly shutdown the reactor in case of abnormality.

- Each reactor protection system also has built-in redundancy satisfying the single failure criterion (i.e. the system must be capable of performing its task in the presence of any single failure).

Barriers

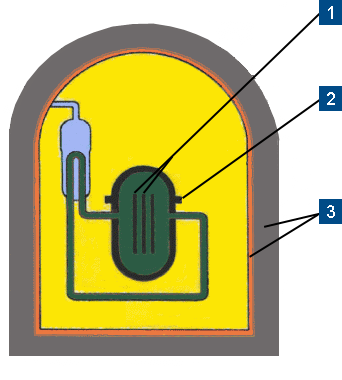

Products of nuclear fission are trapped within the fuel pellets and claddings. There are basically three barriers (i.e. fuel cladding, primary circuit and containment) to prevent the release of these fission products to the environment.

Three barriers of Pressurised Water Reactor

(1) First barrier: fuel cladding

The uranium fuel and the radioactive fission products are sealed inside the zirconium alloy fuel cladding of the fuel rod.

(2) Second barrier: primary circuit

The fuel assemblies are contained within a 20cm thick reactor pressure vessel. The pressure vessel together with the primary coolant circuit form the second barrier to prevent radiological release.

(3) Third barrier: containment

The nuclear reactor and primary coolant system are installed inside a strong and totally enclosed containment building. The containment building has 90cm of pre-stressed concrete wall with 6mm leak tight steel liner. The containment building is the third barrier to prevent radiological release.

Engineered safety features

These systems are installed to protect the plant in case of an accident so as to provide sufficient cooling to maintain the reactor at a safe stable shutdown condition. Major engineered safety features include:

- safety injection system - used to inject borated water into the reactor

- containment spray - used to cooldown and depressurise the containment

- auxiliary feedwater system - used to remove the residual heat from the reactor via the steam generator

Sand filter system

In the event of a serious nuclear accident, radiological materials may be released to the containment from the reactor system. If necessary, the sand filter system can regulate the release of radioactive materials from the containment to the environment to avoid containment failure due to overpressurisation. In this circumstance, the sand filter system would filter/minimize the radioactivity released to the environment.

Emergency planning

GNPS and LNPS have in place combined comprehensive on-site and off-site emergency plans to deal with different emergencies arising from the unlikely occurrence of accidents at various levels and to activate the corresponding and necessary emergency response actions.